ITU thrives to build its new additions to the campus sustainably. Therefore, the water is treated according to LEED standards. Two new buildings (Information Technologies and Agro – Informatics Research Center Buildings) on the campus have applications to get a LEED certification and the water use is minimised according to LEED standards.

Consumption of treated water

IFAS-MBR and MBR System

As a result of the decrease in the discharge limits of wastewater treatment plants, many facilities have to be revised to remove nitrogen and phosphorus. Especially in a metropolis like Istanbul, due to problems such as the inability to design a treatment plant due to space problems, it is necessary to achieve high wastewater treatment efficiency by using smaller areas with innovative methods. At this point, it is planned that these treatment facilities will have effects such as reducing waste discharge and preventing marine pollution. It is planned to purify large amounts of wastewater (including nitrogen+phosphorus removal) in small volumes, especially in areas with space problems, by using innovative systems integrated with membrane systems in pilot-scale treatment plants.

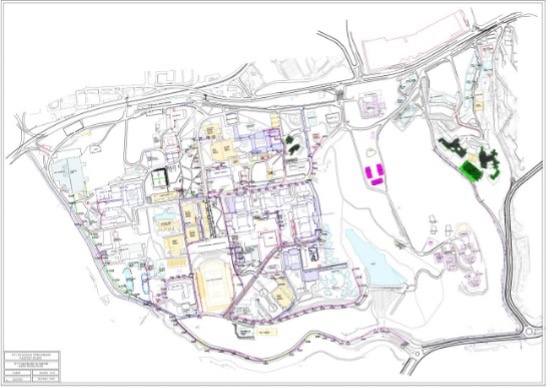

The membrane bioreactor (MBR) pilot system is planned to treat and reuse the wastewater with high COD concentration which is coming from a process that grinds the dining hall waste in İTÜ Ayazağa campus. The pilot system, which includes an MBR module with an ultrafiltration level of 100 m2 surface area, has a flow rate of 20 m3 / hour. Effluent water will be used as sprinkler water.

At the same time, as explained in the declaration presented by the Ministry of Environment and Forestry within the scope of Combatting Mucilage, it is aimed to investigate the vision of using membrane systems that will provide wastewater recovery in the modernization of wastewater treatment facilities and to produce scientific results for the designs. It is necessary to take action to prevent water problems and ensure recycling and to transform existing systems into advanced biological treatment systems.

Within the scope of one of the pilot scale systems, two parallel systems, each with a capacity of 500 L/day, were designed and built. The paralel operating systems treat that wastewater comes from ITU Ayazağa Campus.

The systems were fed with real wastewater of the same characterization and the hydraulic feeding was gradually increased. In this way, organic and hydraulic loading rates were determined for each system and the maximum amount of wastewater that could be treated was determined. Since the most discharge into the Marmara Sea is domestic wastewater, the systems will be used for domestic wastewater treatment within the ITU campus. This system can then be used specifically for all kinds of industrial wastewater treatment. Both pilot plants have the same layout. Aerobic reactors were followed by a membrane reactors (MBR). At the end of the treament, pollutant loading rates decreased 90% percent. Effluent charachteristic is approppriete for the usage of irrigation water.